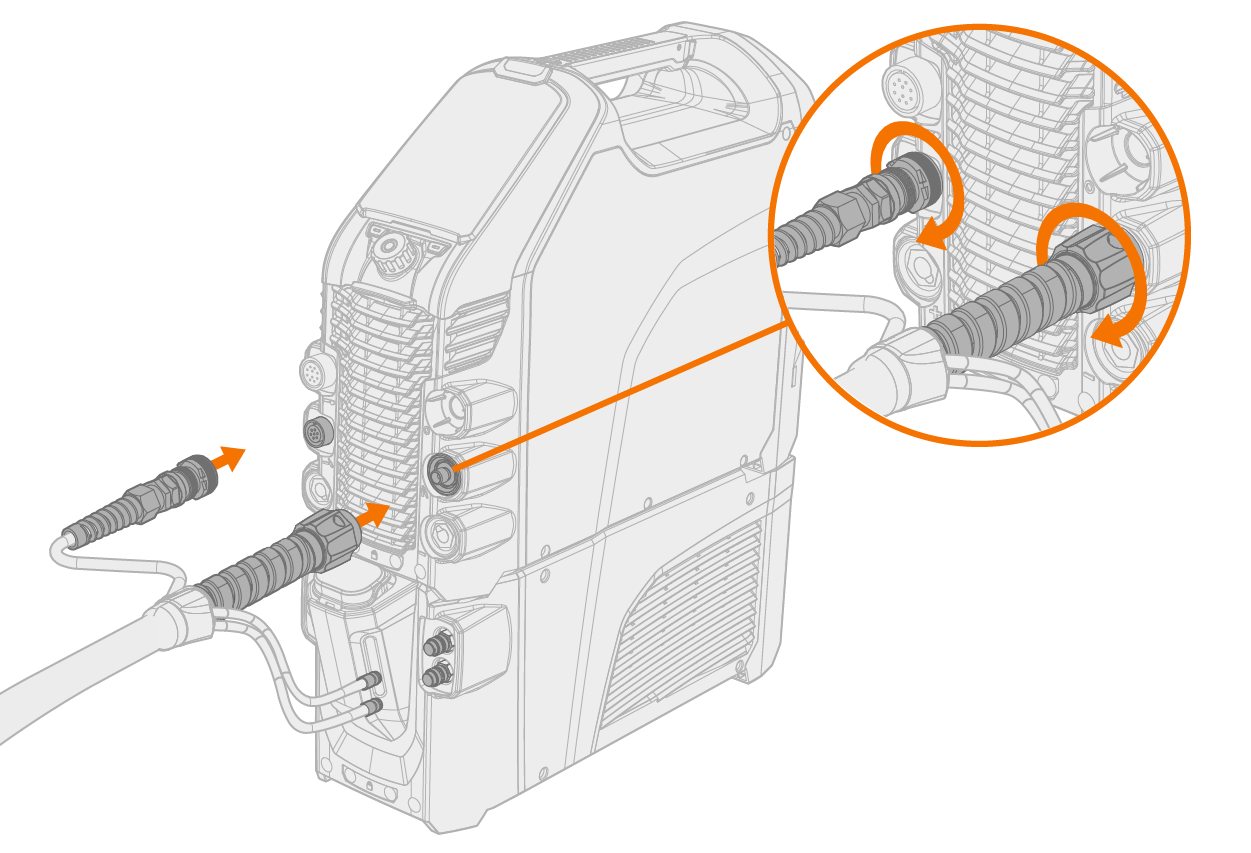

Connecting torch

|

Hand tighten the torch connectors. Loose connectors may overheat, create contact disturbances, mechanical damage and water or gas leakage. |

|

For connecting the torch, refer also to your welding equipment’s instructions. |

Gas-cooled TIG torch (series 5)

|

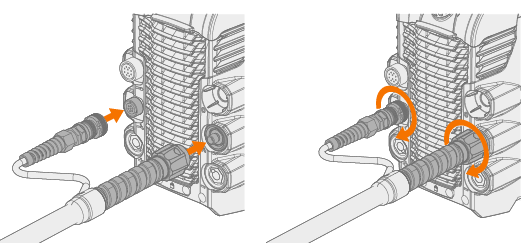

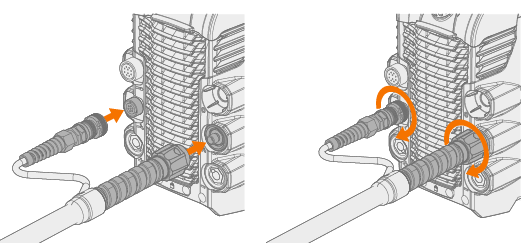

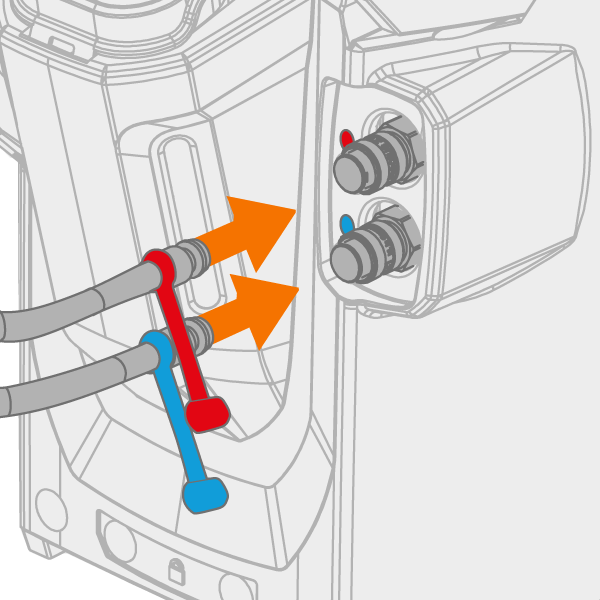

1.

|

Connect the welding cable and the control cable to the power source. Secure by turning the connectors clockwise. |

Water-cooled TIG torch (series 5)

|

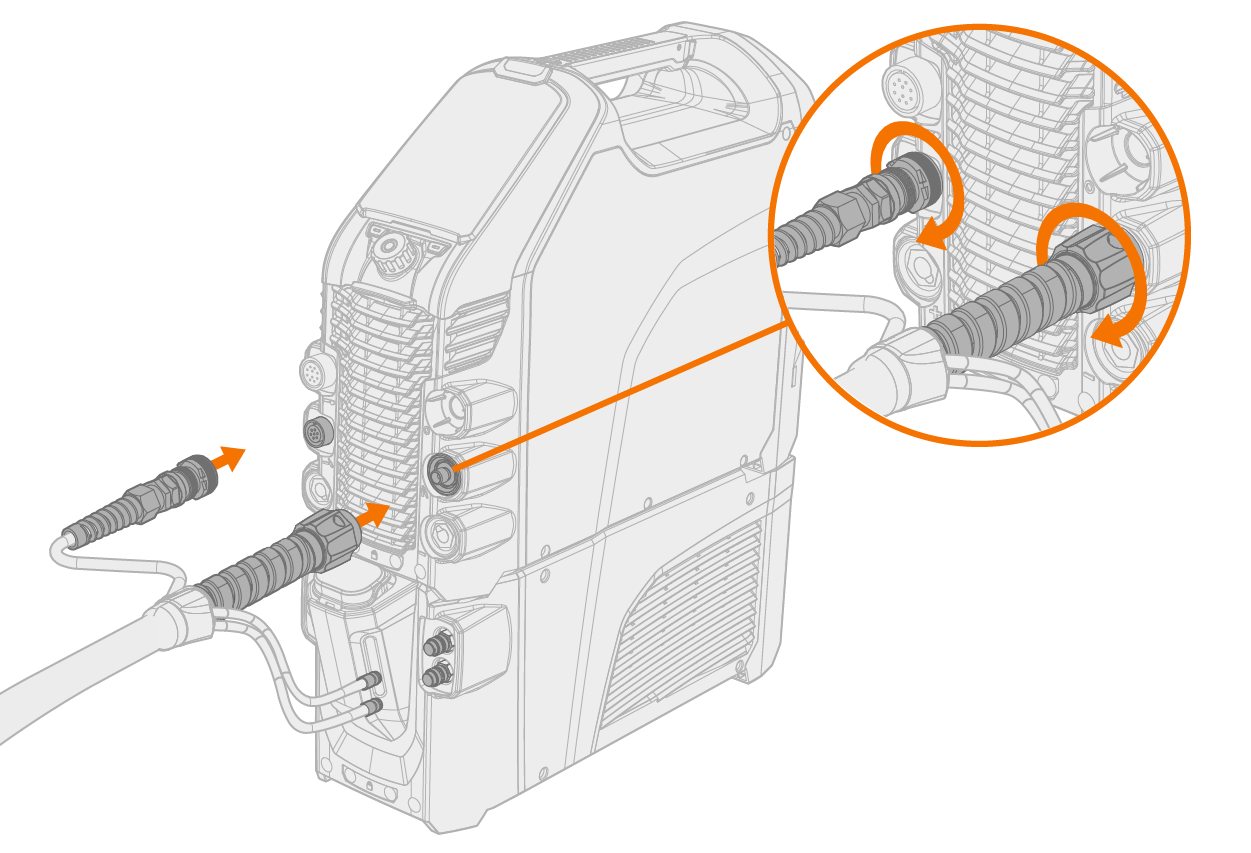

1.

|

Connect the welding cable and the control cable to the power source. Secure by turning the connectors clockwise. |

|

2.

|

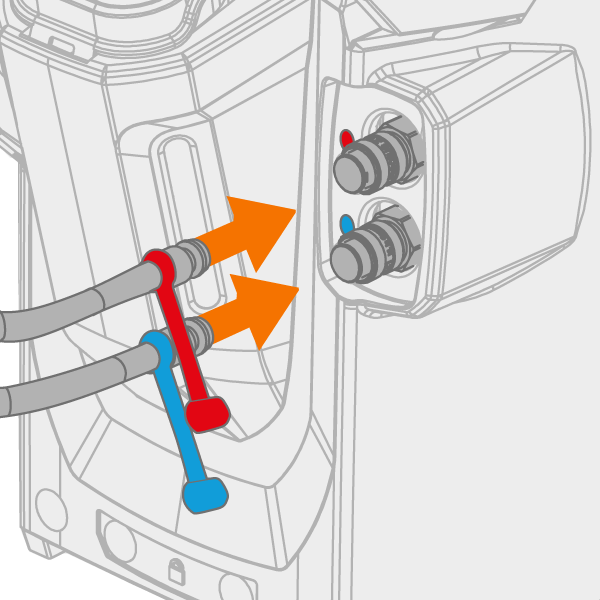

Connect the coolant inlet and outlet hoses to the cooling unit. Note that the connectors are color-coded. |

|

Make sure to connect the coolant hoses to the correct hose connectors. If the connections cross, the

torch and torch body may overheat. |

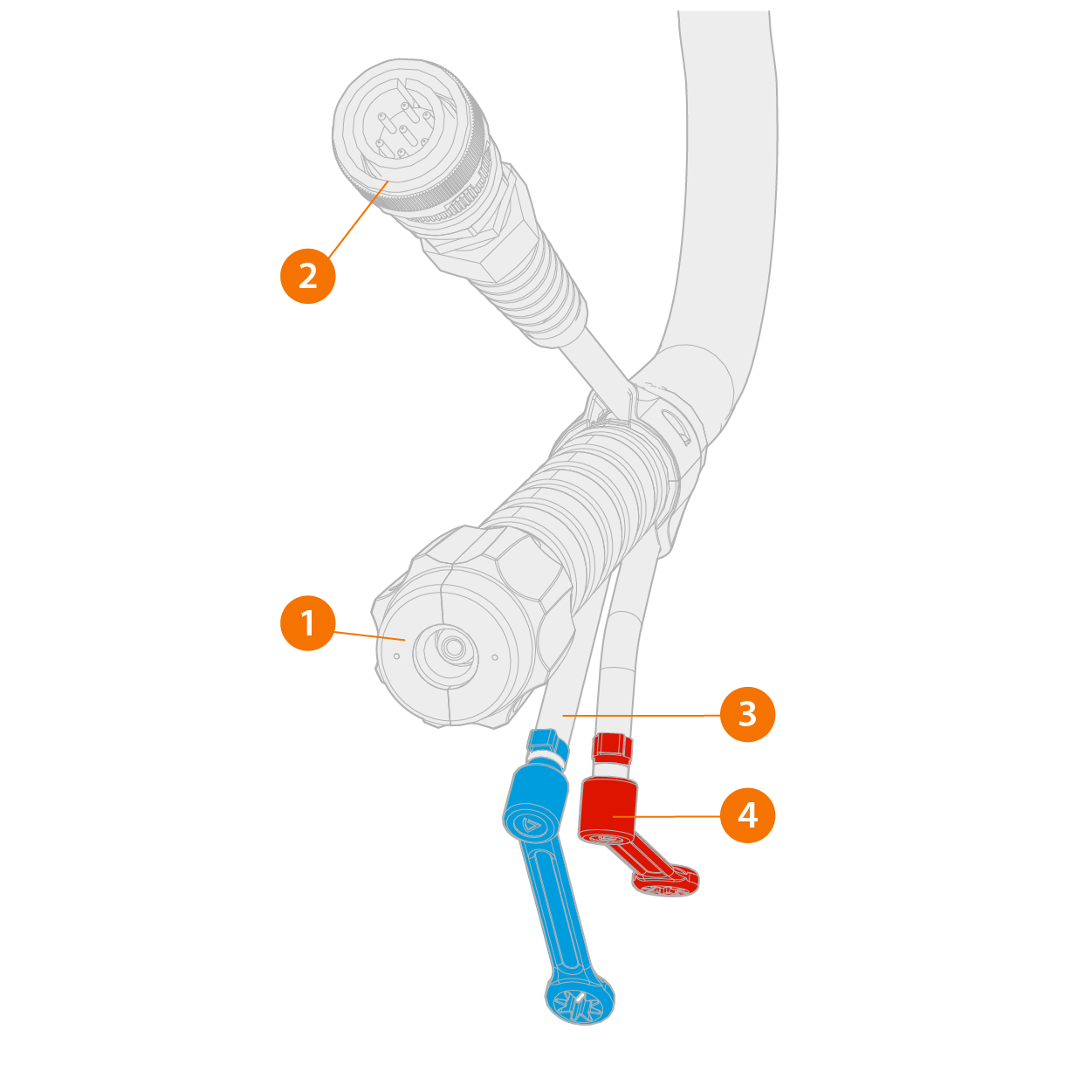

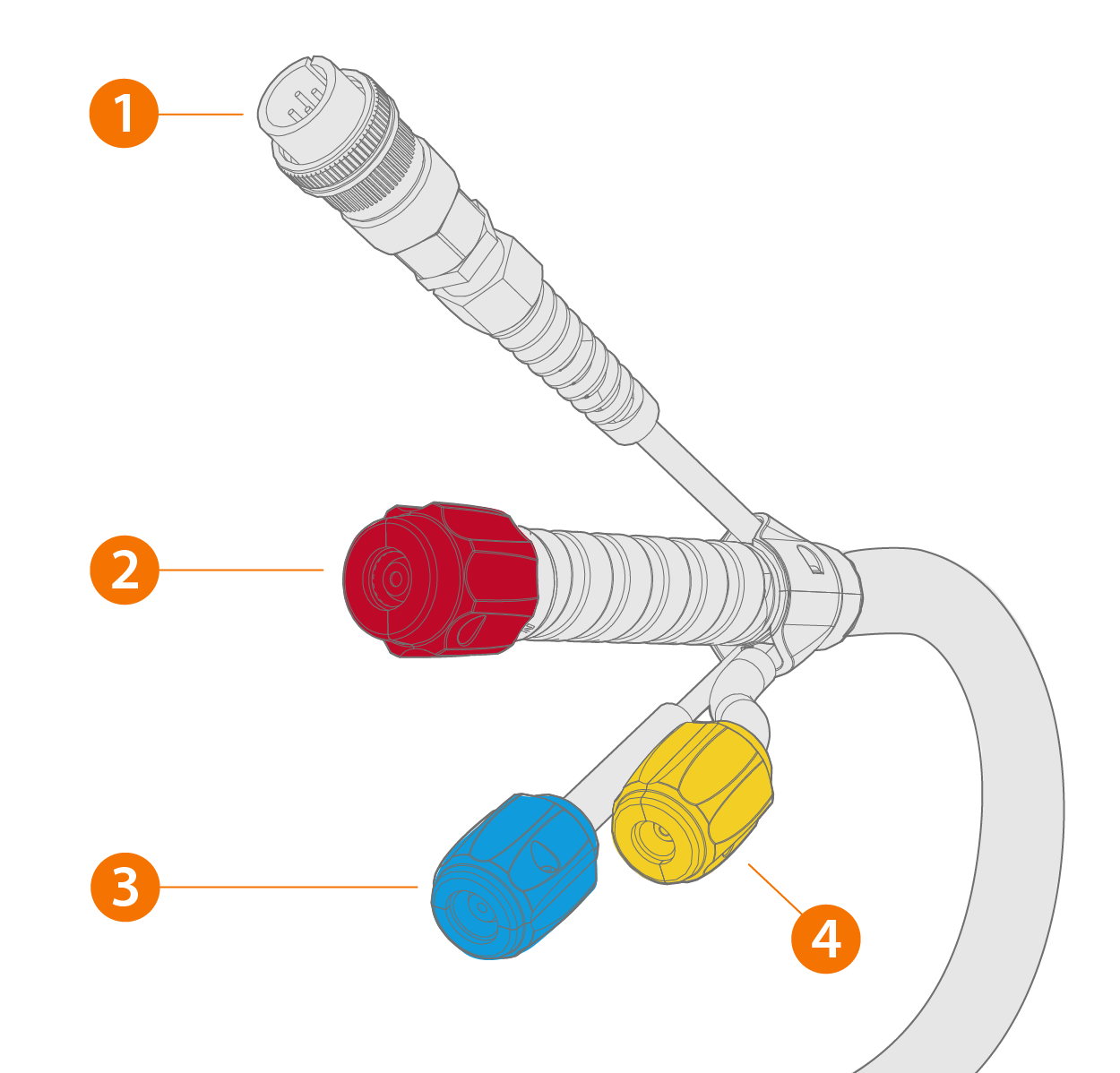

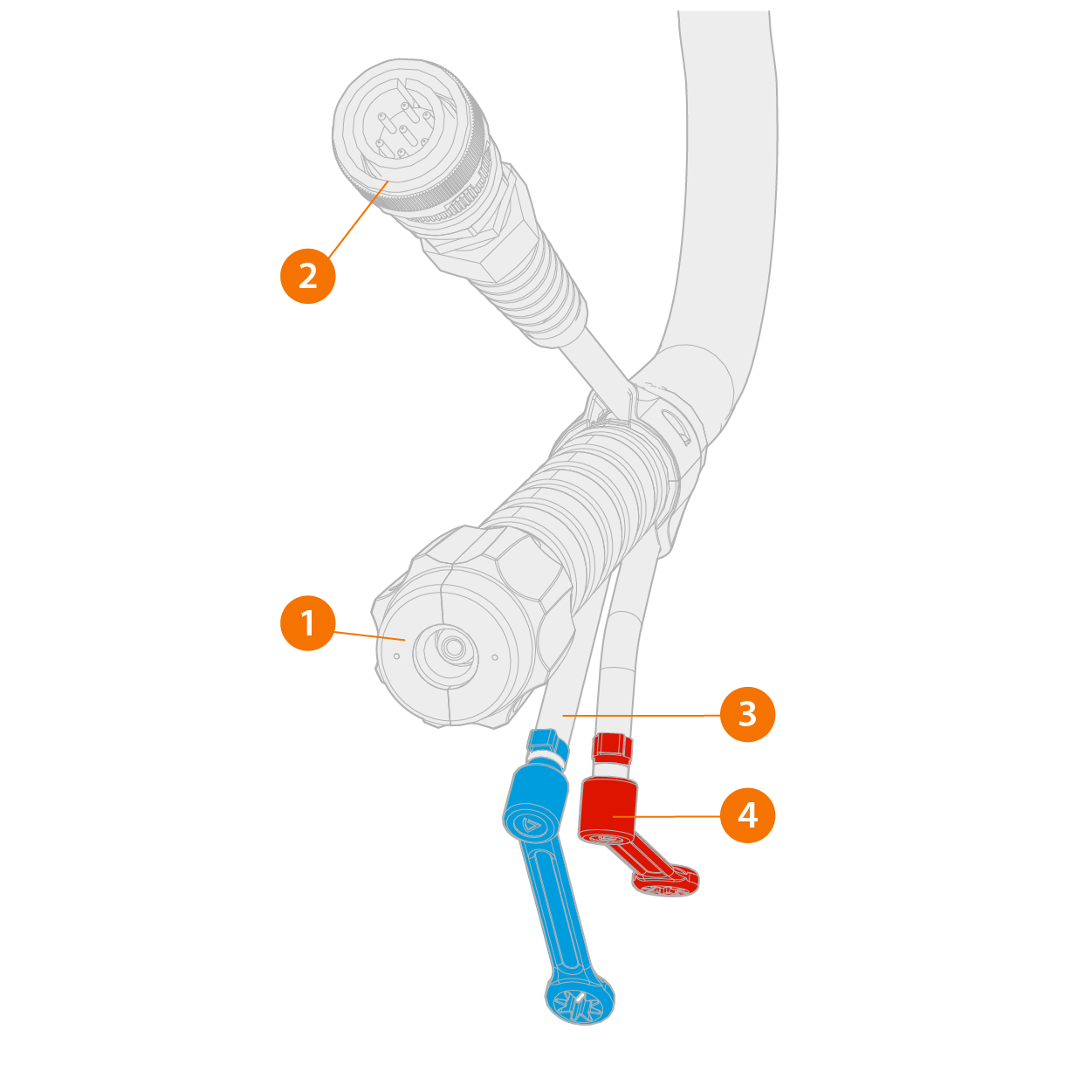

Connectors in TIG torch (series 5)

|

1.

|

Welding cable connector |

|

2.

|

Control cable connector |

|

3.

|

Coolant hose connector |

|

4.

|

Coolant hose connector |

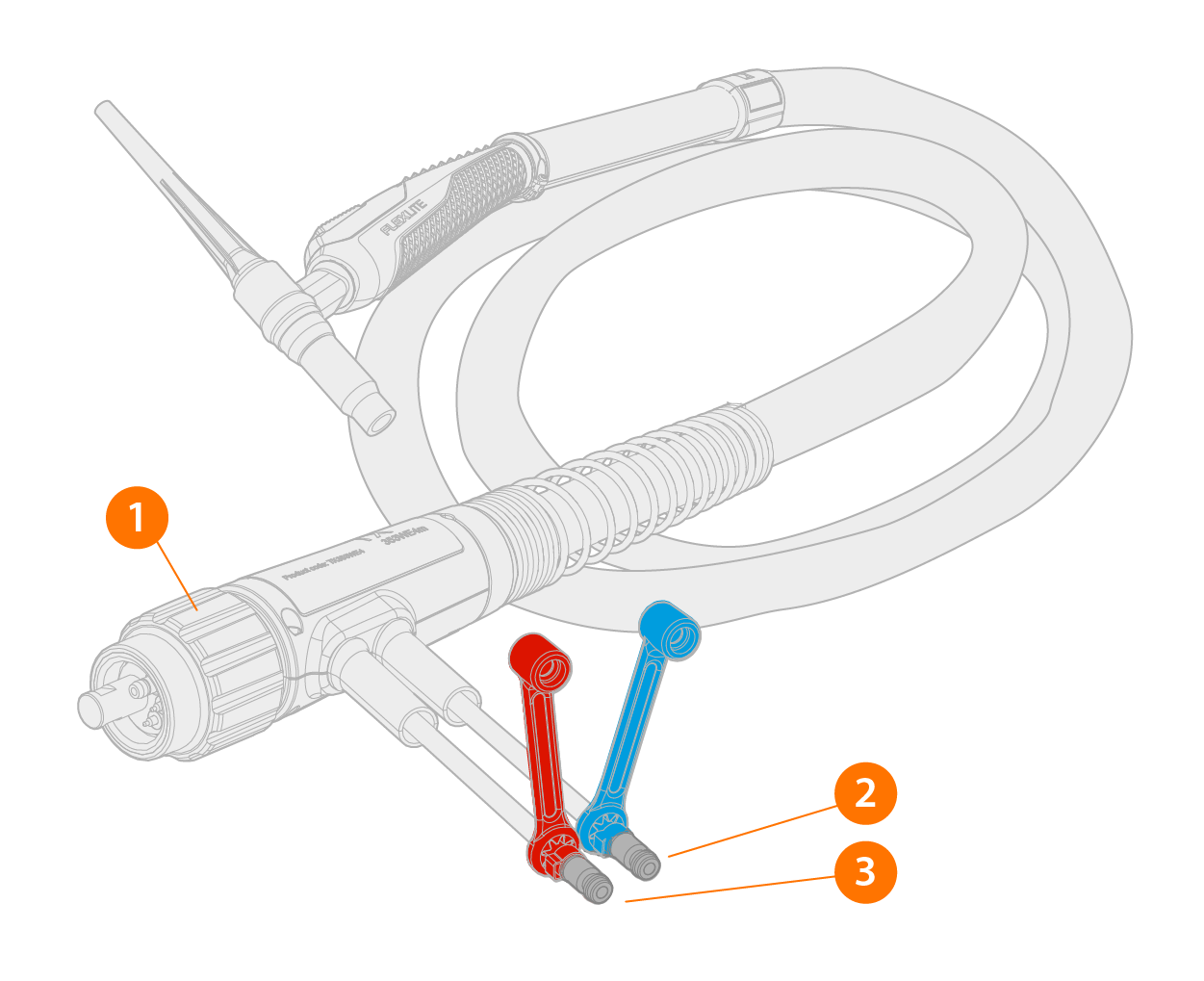

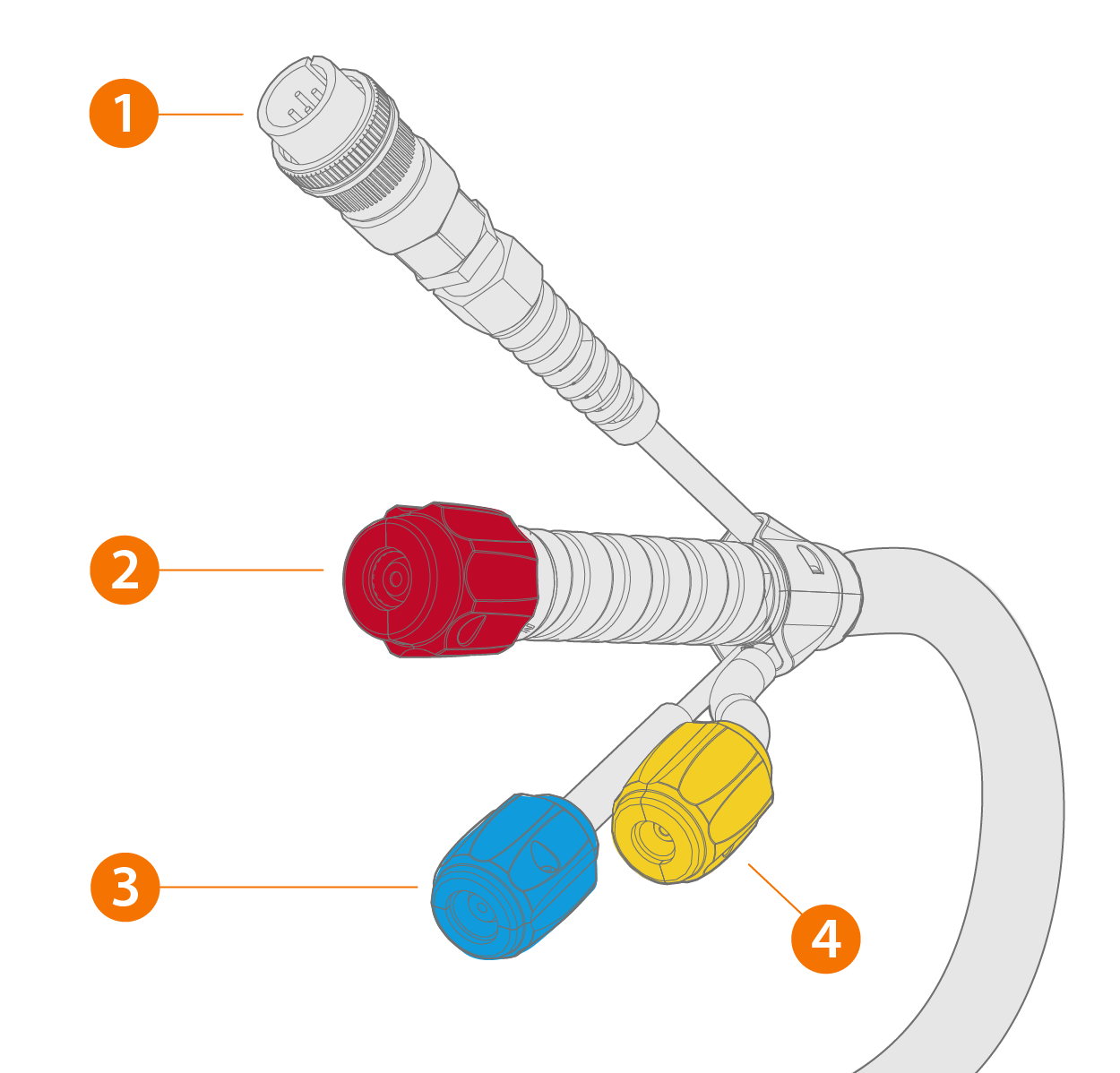

Connectors in TIG torch (series 3)

|

1.

|

Control cable connector. |

|

2.

|

Welding cable and coolant connector. In water-cooled torches this is the coolant outlet hose connector. In gas-cooled torches this is the shielding gas connector. |

|

3.

|

Coolant inlet hose connector (water-cooled torches only). |

|

4.

|

Shielding gas connector (water-cooled torches only). |

|

With series 3 torches that have a DIX connector, use a separate gas hose for gas connection. |

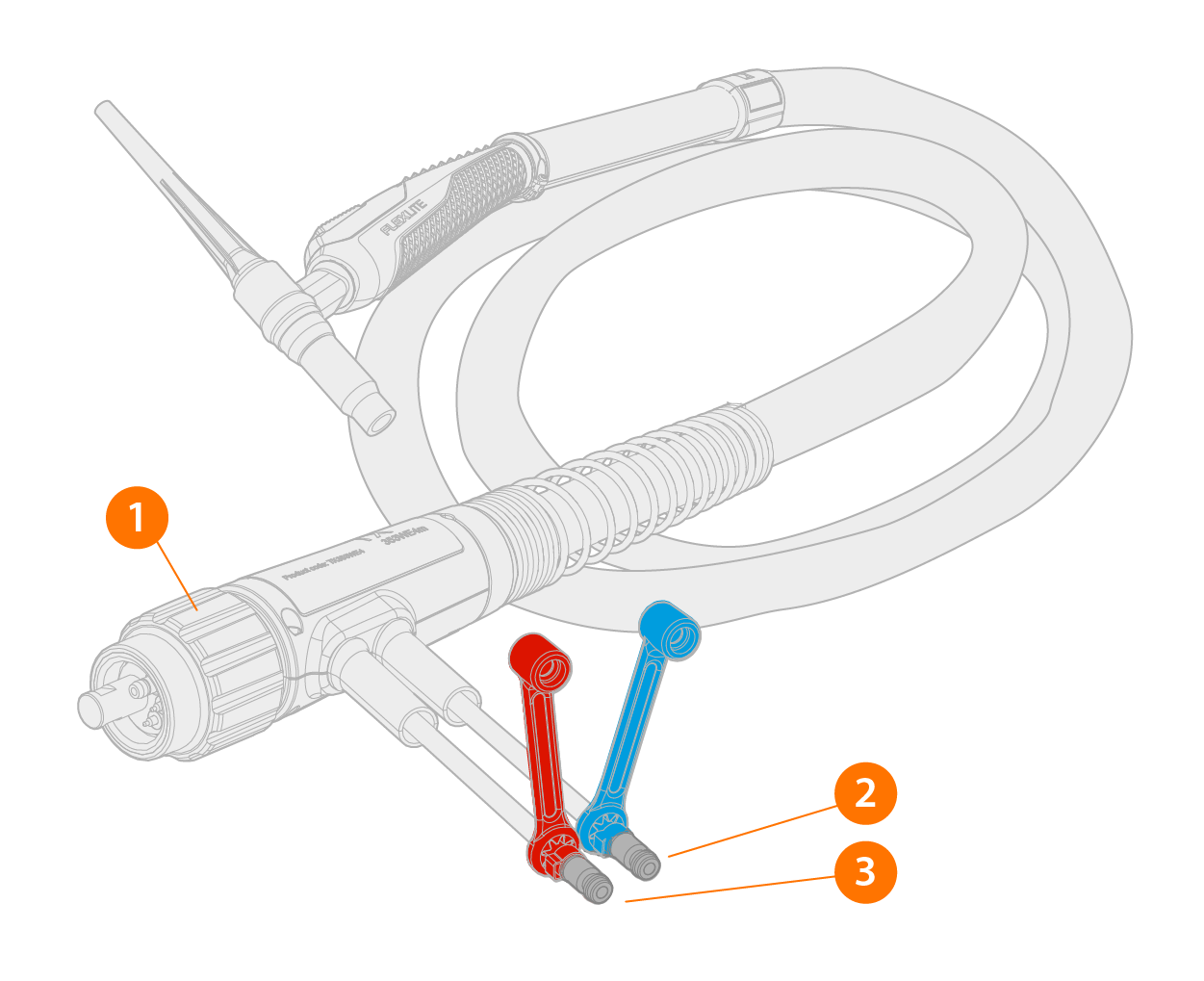

Connectors in TIG torch with euro connector (series 3)

|

2.

|

Coolant hose connector |

|

3.

|

Coolant hose connector |